Electron Microprobe

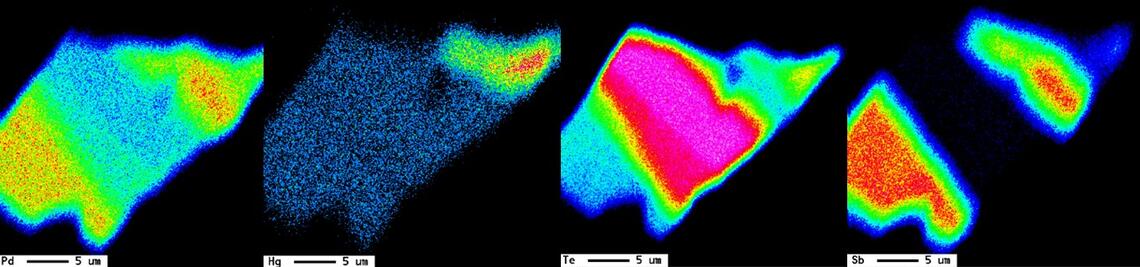

The Department of Geodynamics and Geomaterial Research has a JEOL JXA-8800L electron beam microprobe with four wavelength dispersive spectrometers (monochomator crystals TAP, PET, LIF). The device is well suited for qualitative investigations and for quantitative point analyses of major and minor elements in micro range and in structural environment. A scanning electron microscope device allows visualisation of the secondary electron images and the backscattered electron imaces. The focal points of the analysis, in accordance with the research interests of the department, are petrological, ore petrological, material scientific and archaeometric questions. For the analysis of samples in atypical formats, like archaeological finds, a special sample holder is available.

In addition to the department-internal users, the microprobe laboratory can also be used by external guests. We ask for early consultation regarding the analytical questions, the deadline for the performance of the measurements and the costs:

Dr. Stefan Höhn, Phone 0931-31-85422 oder stefan.hoehn@uni-wuerzburg.de

User´s regulations for the microprobe lab

Measurement conditions for routine analysis:

- Accelerating voltage 15 kV

- Beam current 20 nA

- Beam diameter 1 - 30 microns

- Counting times 20 s/peak and 20 s/background

- Standards ares simply composed element-, oxide- and mineral standards

- Matrix correction ZAF

- Analytical error for major elements < 1% relativ (Na < 2%)

- Detection limit for trace elements 500 - 1000 ppm

For special applications, these measurement conditions may be modified.

For reasons of comparison, our laboratory was involved in a circle analysis, in which a total of 26 European microprobe laboratories participated. Our results (Lab #1 in the result table) are well within the range of variation of the other laboratories:

Electron microprobe circle analysis

To get information about the general reliability of electron microprobe analyses carried out in different laboratories with different machines, an international circle analysis project was initiated and organized from 1994 on. A sample holder was produced containing three homogeneous mineral samples typical for petrological material:

- Olivine from St. John, Scotland, contributed by A. Kirfel, Institut for Mineralogy and Petrography, University Bonn

- Garnet, synthetic, contributed by T. Fehr, Institute for Mineralogy, Petrology and Geochemistry, LM University Munich

- Feldspar, Lake County, Oregon, contributed by J. Koepke, Institute for Mineralogy, University Hannover

The sample holder was in succession sent to 26 participating labs and was newly polished and cleaned after coming back from each lab. Each lab measured minimum 10 spots on each mineral under routine analytical conditions and submitted the analyses with average and standard deviation (1 s) before knowing about the results of the other labs.

The following table gives an overview concerning the variability of data of all 26 labs with minimum and maximum values measured, the difference between minimum and maximum values, the average of analyses from all labs with 1 s standard deviation and, calculated from this, the relative interlaboratory error:

|

A table with the average compositions from each lab together with intralaboratory standard deviation is available here (table of results). The labs remain anonymous and are marked by numbers. The order of labs in the table is not consistent with an alphabetic list of the participating institutes at the end of this page.

For the future, the sample holder used for the circle analysis is available for all microprobe labs as a tool to check the own analytical reliability concerning silicate minerals. The sample holder will be delivered with newly polished samples, but without carbon coat. Please turn to

Dr. Stefan Höhn, Tel. 0931-31-85422 oder stefan.hoehn@uni-wuerzburg.de

The following institutes and labs have participated in the circle analysis:

GERMANY

- Bayreuth: Bayerisches Forschungsinstitut für experimentelle Geochemie und Geophysik der Universität (Volker von Seckendorff)

- Berlin: Zentraleinrichtung Elektronenmikroskopie (ZELMI) der TU (Francois Galbert)

- Bochum: Zentrale Elektronen-Mikrosonde der Ruhr-Universität (Heinz-Jürgen Bernhardt)

- Bonn: Mineralogisch-Petrographisches Institut der Universität (Jürgen Ehl)

- Clausthal-Zellerfeld: Institut für Mineralogie der TU (Karsten Gömann, Klaus Hermann)

- Darmstadt: Fachbereich Chemische Analytik der TH (Sebastian Riedl)

- Frankfurt am Main: Institut für Mineralogie der Universität (Thomas Stachel)

- Freiburg: Institut für Mineralogie, Petrologie und Geochemie der Universität (Hiltrud Müller-Sigmund)

- Giessen: Institut für Geowissenschaften und Lithosphäreforschung der Universität (Rüdiger Borchardt)

- Göttingen: Zentrum Geowissenschaften der Universität, Abt, Geochemie (Andreas Kronz)

- Hamburg: Institut für Mineralogie der Universität (Barbara Cornelisen)

- Hannover: Institut für Mineralogie der Universität (Jürgen Koepke)

- Heidelberg: Mineralogisches Institut der Universität (Hans-Peter Meyer)

- Kiel: Geomar Forschungszentrum (Petra Glöer)

- Kiel: Mineralogisch-Petrographisches Institut der Universität (Dietrich Ackermand, Barbara Mader)

- Köln: Mineralogisch-Petrographisches Institut der Universität (Gudrun Witt-Eickschen)

- Mainz: Institut für Geowissenschaften der Universität, Mineralogie (Burkhard Schulz-Dobrick)

- Mainz: Schott Glaswerke, Abt. Glasfehleranalytik/Mineralogie (Bernhard Valentin)

- München: Institut für Mineralogie, Petrologie und Geochemid der LM Universität (Thomas Fehr)

- Münster: Institut für Mineralogie der Universität (Michael Enders)

- Potsdam: GeoForschungsZentrum GFZ (Dieter Rhede,Wolfgang Seifert)

- Würzburg: Institut für Mineralogie der Universität (Uli Schüssler)

AUSTRIA

- Wien: Institut für Petrologie der Universität (Theodoros Ntaflos)

FINLAND

- Espoo: Geologian Tutkimuskeskus (geological survey), Espoo (Kari Kojonen)

SWEDEN

- Uppsala: Institutionen för Geovetenskap, Mineralogi-Petrologi, Universitet Uppsala (Hans Annersten

SWITZERLAND

- Basel: Mineralogisch-Petrographisches Institut der Universität (Susanne Schmidt)

Regulations for the use of the electron microprobe

According to the decision of the Department of Geodynamics and Geomaterials Research of the University of Würzburg from the 08.11.2010, the use of the Electron Microprobe Laboratory is regulated by the following usage regulations.

Please note: The device is subject to the radiation protection regulations of the department!

1. Laboratory equipment

The core of the laboratory is a JEOL JXA-8800L electron beam microprobe with 4 wavelength-dispersive X-ray spectrometers, secondary and backscattered electron detectors and a subsequent update of the computer control by a Unix Sun workstation. The analytical possibilities include the display of scanning electron images, a qualitative analysis, a quantitative analysis of the major and minor elements from atomic number 11 (Na) onwards by means of point analyses at a spatial resolution of > 2 micrometres and the creation of element distribution images (mapping). The analysis of trace elements is not carried out routinely, but is possible in certain cases. The routine analysis primarily refers to geological sample material, i.e. rock-forming minerals, ore minerals, in a broader sense also to archaeological and modern materials. Samples with the following dimensions can be analysed as standard:

- Rectangular specimens with dimensions 48 x 8 mm; thickness of specimens maximum 2 mm; surface polished accordingly; not covered (thin sections, scattered specimens).

- Round samples with diameters of 25 mm or 39 mm; thickness of samples maximum 2 cm; surface polished accordingly; not covered (ore cuts, cast-in samples).

- Small, irregularly shaped polished objects with a maximum size of 40 x 50 x 18 mm (e.g. archaeological samples, unformatted ore samples, material samples).

The samples must be thoroughly cleaned before measurement and vapour-deposited with a carbon layer approx. 150 nm thick for charge dissipation.

2. Sample preparation

Professional sample preparation is a basic prerequisite for a meaningful measurement. By default, only samples whose surface is flat and appropriately polished (polish finish: 0.25 - 1 μm) are examined. If necessary, the quality of the sample surfaces to be examined can be checked by the supervising persons. If the quality is not sufficient, it is strongly recommended to have the preparation carried out at the institute, possibly at a charge. Before a sample can be analysed, some important steps must be carried out by the user.

2.1 Measurement appointment

Appointments for measurements are requested from the supervising persons (by telephone, e-mail or in person) and entered in a calendar. All appointments are non-binding, as disturbances can occur in the laboratory at any time, which result in a rescheduling. Significant changes to the measurement plan, which may result from a microprobe standstill with a longer service call, are discussed in consultation with the working group leaders, taking into account in particular the urgency of a measurement project (e.g. deadline for BSc theses).

2.2 Sample preperation

Sample preparation must be ordered in good time from the staff member responsible for the preparation laboratory. First-time users (e.g. students in the context of study qualifying work) should definitely have a preliminary discussion with the supervisors of the probe about the type of preparation or the number of samples.

A solid time planning for a measurement project is an absolute prerequisite for the realisation of the analysis. The individual steps are: 1. selection of samples, 2. sample preparation, 3. preparatory work with the light microscope, 4. marking of the measuring areas, 5. photographic documentation of the measuring areas, 6. vapour deposition on the sample, 7. actual analysis. In any case, the polished sample(s) should be available in the microprobe laboratory a few days before the measurement date (rule: 5 working days), as the samples still have to be vapour-deposited before the measurement and there cannot be a separate vapour-deposition for each sample.

2.3 Prior to the measurement

- The samples must be examined with the light microscope before the actual microprobe analysis.

- Points of interest should be marked for this purpose.

- Before handing over the samples in the microprobe laboratory, the surfaces of the samples must be carefully cleaned.

- Experienced users should independently install the samples in the sample holder on the day of the measurement and have clarified before the measurement which analysis settings are to be used.

- First-time users should provide the supervisors with the information on which sample to start with, which elements to measure, and whether any special measurement options are to be applied (e.g. profiles, qualitative investigations, element mapping, trace element measurements, etc.) at the latest on the day before the measurement session.

3. Costs

The costs of the laboratory are made up of two items:

1. Costs for acquisition and operation

- Electricity, water, air conditioning

- Support office

- Repair costs

- Replacement of electrical and mechanical components that do not correspond to typical wear parts (e.g. power supply units; vacuum pumps; computers)

2. Costs for carrying out the measurement operation and for ensuring the quality of the analysis

- Costs for special gases (argon/methane and nitrogen)

- Running costs for consumables (e.g. filaments, apertures, counting tube windows, spectrometer windows)

- Costs for maintenance and service (e.g. column cleaning; adjustment work; cleaning of the sample chamber; maintenance of the X-Y-Z stage and the spectrometers; maintenance of the vacuum components; maintenance of the ion getter pump)

- New acquisition or subsequent purchase of certified standards

For the calculation of the proportional laboratory costs that can be allocated to academic users, only the laboratory costs for carrying out the measurement operation and for ensuring the quality of the analyses were taken into account (second item, based on the last few years). This results in the following flat rates for use for different user groups:

• 150 € / day - for all academic work carried out by members of the department (under the responsibility of the respective working group leaders) as well as for those guests who cooperate directly with the working group leaders in joint projects.

• 250 € / day - for university members who are not part of the Department of Geodynamics and Geomaterials Research and for such guests who do not cooperate with the working group leaders within the framework of projects. For these measurement projects, once the microprobe has been powered up and set up, the whole day is available until the next morning (9 am). Help with measurement-related problems can usually be provided between 9 am and 5 pm. However, it is assumed that the user is able to operate the device independently after instruction.

• 200 € / hour or 2000 € / day - for third parties (companies) within the framework of commercial contract analysis. These costs include measuring device time, intensive supervision of the project by the operator, evaluation of the data, writing of a report. For automated measurements, the whole day is available until the next morning (9 am). In general, the costs for sample preparation (preparation of thin sections, carbon sputtering, etc.) are not included in the fees for the use of the microprobe. Instructions for sample preparation should be requested in advance.

Würzburg, 13.12.2021

Dr. Stefan Höhn, Tel. 0931-31-85422 oder stefan.hoehn@uni-wuerzburg.de